Validation, as a food safety management requirement, has been done since the inception of HACCP especially for Critical Control Points (CCPs). In recent years, however, new versions of global food safety standards and legislation have introduced the requirement to validate non-critical controls such as PRPs, oPRPs, and general preventive controls.

In this article, we will focus on the validation of cleanliness, a commonly used and important preventive measure. We will discuss the importance of cleanliness, why validation is necessary, and best practice methods of validation that are commonly used.

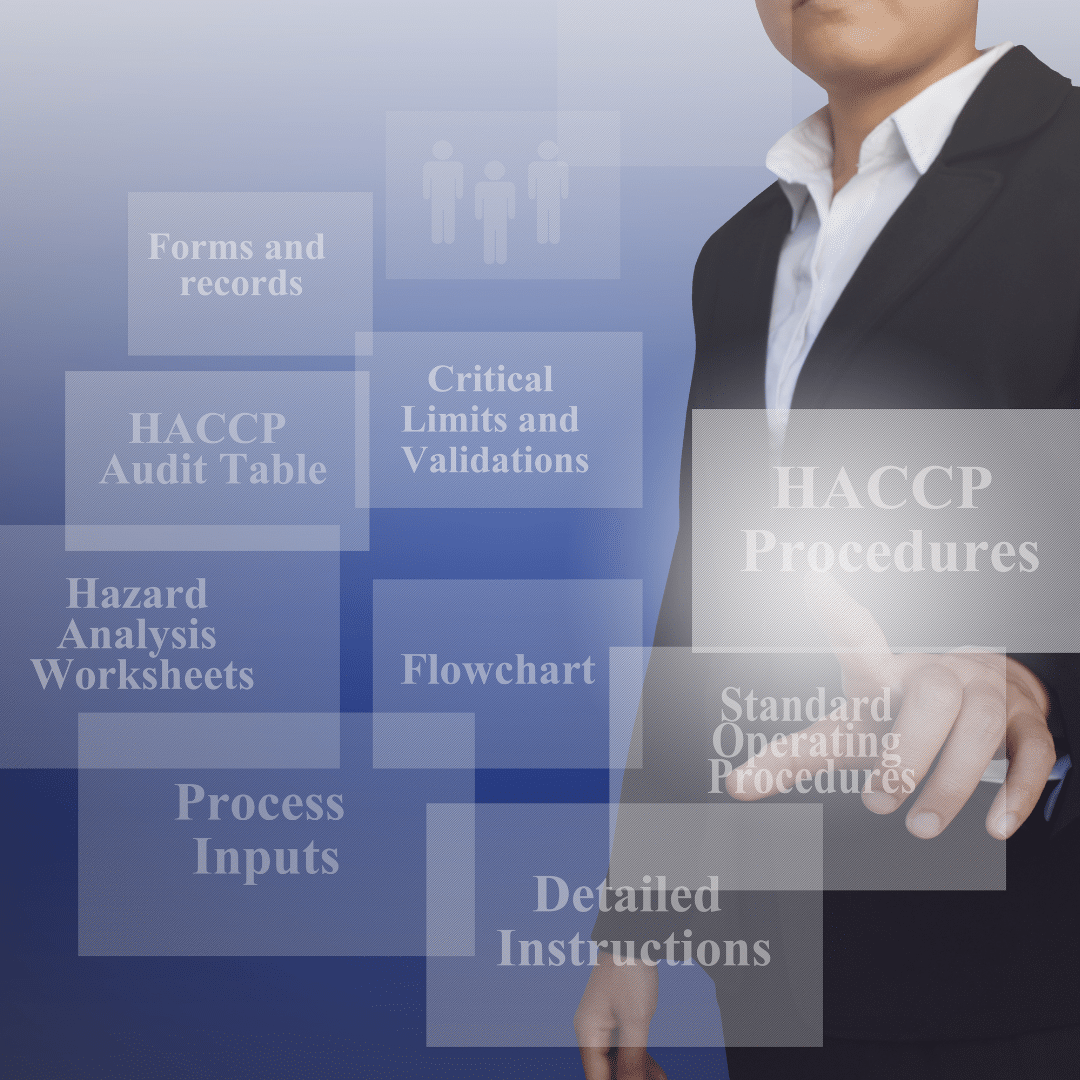

Food safety management systems often place HACCP at the center of control for specific food hazards. This is particularly meaningful where a specific hazard can be identified that is linked to adverse effects for the consumer.

The most important rule of an effective HACCP system is traceability, which requires a basic control program for general hazards that cannot be identified.

These programs have been described as Good Manufacturing Practices (GMP), Prerequisite Programs (PRP), and Preventive Controls (PC) to name a few. Regardless of the term used, they all represent a basic requirement of good practices to ensure a safe environment for food production.

Among the most important of these is the need to adequately clean and sanitize your facility and equipment from chemical and microbiological hazards to produce physically and allergy-free food. In addition, it is important to understand why a food facility needs to be cleaned. We can list them as follows:

- To reduce risks from food hazards – food poisoning and foreign contamination

- Comply with local and international legislation

- To meet specific customer requirements

- To meet the requirements of Global Food Safety Standards (GFSI)

- Maintain positive audit and audit outcomes

- Allowing maximum plant productivity

- Presenting a hygienic visual image

- Promote safe working conditions for staff, contractors, and visitors

- Maintain product shelf life

- To avoid pest infestation

- At the most basic level, the visual appearance of a food factory is an indicator of the company’s standards and culture.

It has a strong impact on the perception of an auditor or visitor. It can influence the overall outcome of inspections and help secure new business. Therefore, the visible cleanliness of a company is just as important as detailed HACCP plans.