In this article, we will look for the answer to the question “What is HACCP?” and see how the world has produced answers to this question.

The world is in an era of digital transformation. So we can talk about the continuity of change. It is best to adapt to these changes both intellectually and in terms of action plans.

Societies are always in change by nature. For these changes to take place healthily, control and supervision mechanisms have emerged. These mechanisms in these processes are of great importance. This has become a necessity to prevent corruption or negative situations during both scientific and social changes. This approach makes itself felt especially in developed civilizations.

HACCP is exactly the approach we encounter in this regard. If we are talking about a process that prioritizes health and food safety in the country we live in, we cannot ignore the HACCP system and HACCP principles. For this reason, the HACCP system should be followed.

Because nutrition is the most important source of quality in our lives and the most important source of sustaining our lives, and in this case, the HACCP system has some things to tell us about ensuring social welfare.

What is HACCP?

HACCP is a concept that emerged in the mid-20th century.

First of all, let us clarify what the letters HACCP stand for;

HACCP stands for: “Hazard Analysis and Critical Control Point“.

It would be very accurate to draw the following conclusion.

A systematic approach that examines food safety in detail and prevents hazards that

are likely to threaten human health.

HACCP History

When we look at the origin of HACCP, we go back to the late 1950s. When you examine different sources, the emergence of this concept is mentioned between 1955~1959. So when you look at it, there is a history going back 70 years.

It is known that scientists and engineers interested in food played a major role in the emergence of this concept. The scientists who created the HACCP systematic consisted of employees of the following organizations and institutions:

- The Pilsbury Company, once the largest food producer

- US Army Soldier System Center

- NASA

The HACCP system was put forward by people working in the most important pillars of the American system.

The main goal of these scientists was to make the space program with the USSR more efficient. The space program was facing many problems. One of them was how to ensure proper food and nutrition techniques. Today, the HACCP system is used by NASA and the US Army’s Military Systems Center and is also used in the food industry.

What Does HACCP Do?

When answering the question “What is HACCP?”, we also need to know what this HACCP does. In this way, we will be able to visualize the application examples of HACCP in our minds.

The main objective of HACCP is to make the food production and consumption stages as healthy as possible. It therefore prioritizes social welfare and hygienic requirements.

HACCP is also critical for the development of institutions and organizations. Because it sets standards that provide great benefits in an important process such as risk management. In this respect, it also gives businesses and organizations the chance to guarantee their future success.

What are the benefits of HACCP applications?

In this section, where we will examine the benefits along with the question “What is HACCP?”, we can see what benefits HACCP provides to businesses.

Based on food safety, this system is a guide that identifies the main controls over the process and plans how they should be managed.

From this point of view, it has extremely important benefits for both businesses and institutions and public health: The main advantages of HACCP standards are as follows:

- It prevents possible risks in food by controlling the production and distribution system.

- Creates awareness about food hygiene.

- It plays an important role in protecting consumer health.

- It helps to improve the quality of goods and products in circulation.

- Helps to improve all systems in food hygiene and food safety.

- Increases the value of brands, organizations and institutions.

What are HACCP Principles and Implementation Steps?

The HACCP Certificate does not have an official accreditation approval, so as a complementary ISO 22000 Standard can be certified as Accredited by TURKAK.

There are 7 basic principles in the HACCP system. Each of these principles describes how management plans should be made and maintained within production.

1-) Hazard Analysis

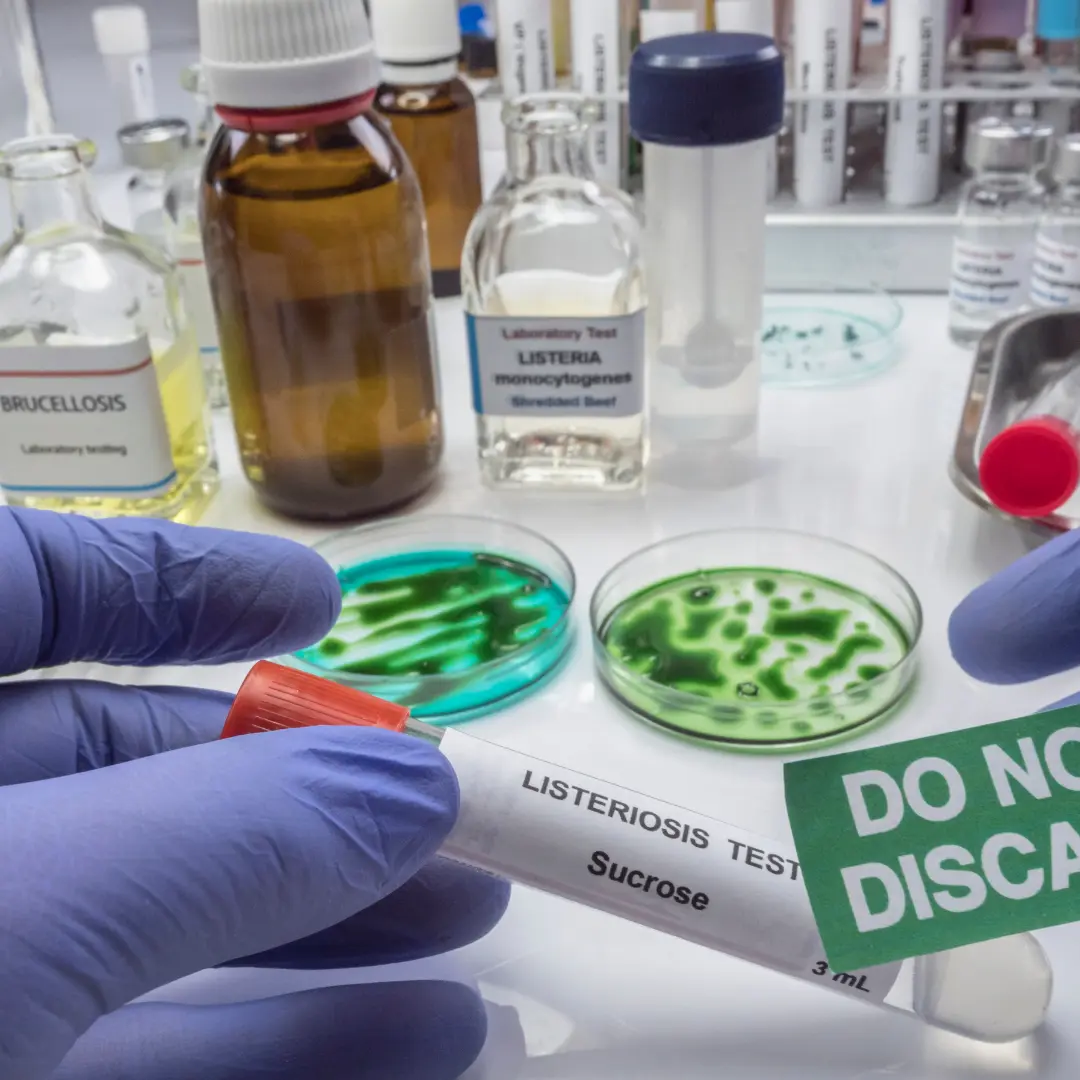

The first step aims to prevent hazards such as injury and illness. Biological, chemical, and physical damage is identified and efforts are made to prevent it before it occurs. In the first step, the hazard is defined. The damage that the hazard will cause in response to the possibility of occurrence is emphasized. Risks and hazards are then categorized and work is started to reduce undesirable situations.

2-) Identification of Critical Control Points

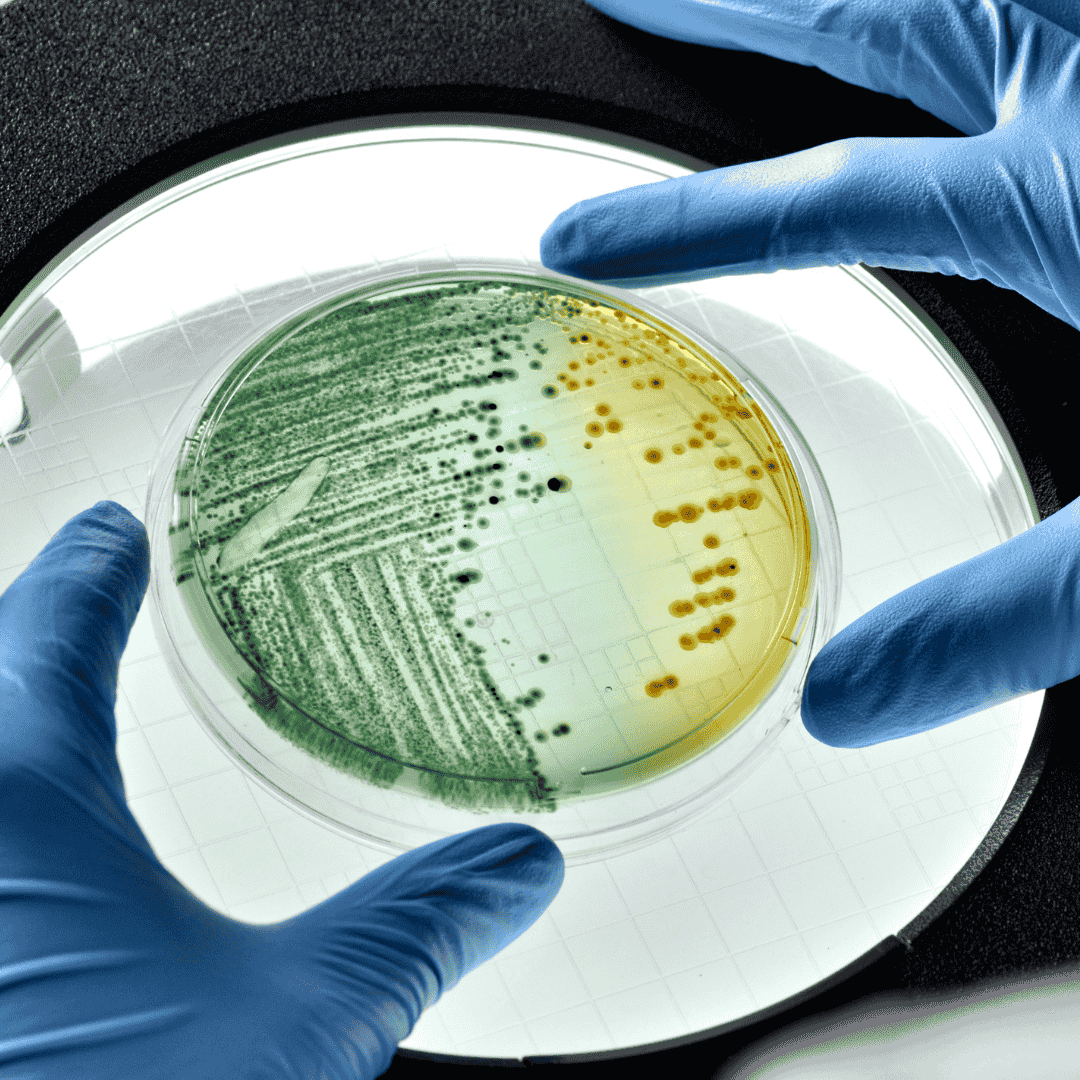

This step defines how control and inspection can be implemented. Setting critical control points aims to eliminate the food safety hazard. If it is not possible to eliminate the hazard, it brings it to a minimum level that will not harm anyone. The control point identified by the HACCP team is at least one. Control points are determined separately for possible hazards.

3-) Determination of Hazard Limits

In this step, the minimum/maximum values to be controlled for a physical, chemical, or biological parameter are determined. Once the critical control points are identified, the limits are determined by scientific methods. At this stage, regulatory standards, experts, and experimental data can be used.

4-) Establishment of Monitoring Procedures

Monitoring the process is crucial to facilitate the management process. In this step, a planned sequence of observations and measurements is determined. Monitoring and follow-up are used to detect deviations in the process. At this stage of continuous monitoring and follow-up, transactions and practices are also recorded.

5-) Implementation of Corrective Actions

This step is to prevent unsafe food from reaching consumers. If a deviation has occurred in the previous steps, out-of-control products may reach the market. This step is intended to prevent the distribution of products and goods that have not been identified as damaged in the process.

6-) Record Keeping Methods

The HACCP system records contain a summary of the hazard analysis in general terms. The purpose of this record summary is to prevent audits and critical situations. The basic principles of HACCP and each process in the implementation steps are recorded. Thus, this recorded data can guide the solution of important problems in the future and current applications.

7-) Verification Procedures

This step includes record review, independent testing, and observation/monitoring methods. Verification procedures, the final step in HACCP principles, outline specific ways and means. The final step in HACCP is to measure the soundness of the plan. Measurement and verification are based on scientific processes. If verification

You can follow your HACCP standards with Qualiqo, a sanitation software that complies with HACCP standards. For more information, you can request a Demo Form.