Risk-Based Sampling in Environmental Monitoring Programs (EMP)

Environmental Monitoring Programs play a vital role in controlling microbiological risks in food production facilities. However, in many operations, EMPs are still treated as routine sampling activities conducted at fixed locations and predefined intervals.

While this approach may support basic audit compliance, it often fails to reflect actual operational risks. Changes in process flow, variations in sanitation performance, pest activity, and product risk levels all directly influence the effectiveness of environmental monitoring.

For this reason, modern food safety systems require EMPs to evolve into risk-based , data-driven, and preventive programs. A RB EMP approach structures sampling plans around potential contamination risks, strengthening food safety while ensuring more efficient use of resources.

Why EMP Must Be Risk-Based

Environmental Monitoring Programs play a critical role in early detection of microbiological risks. However, many EMPs still rely on fixed sampling plans that fail to reflect real operational risks. Risk-based EMP transforms environmental monitoring into a dynamic risk management tool.

What Is a Risk-Based EMP?

A risk-based EMP defines sampling locations, frequency, and scope based on potential contamination risks rather than static routines. The goal is not more sampling, but smarter sampling.

Key Factors in Risk-Based EMP Sampling

Table: EMP Risk Factors

| Risk Factor | Description | Monitoring Impact |

|---|---|---|

| Process Flow | Raw to RTE transitions | Priority zones |

| Sanitation Performance | Cleaning effectiveness | Frequency adjustment |

| Pest Activity | IPM trends | Location review |

| Historical Results | Positive trends | Risk-driven focus |

| Product Risk | High-risk products | Expanded scope |

Traditional vs Risk-Based EMP

| Traditional EMP | Risk-Based EMP |

|---|---|

| Fixed sampling points | Dynamic risk zones |

| Static frequency | Adaptive frequency |

| Retrospective analysis | Predictive insights |

| Audit-driven | Preventive |

| Isolated evaluation | Integrated data |

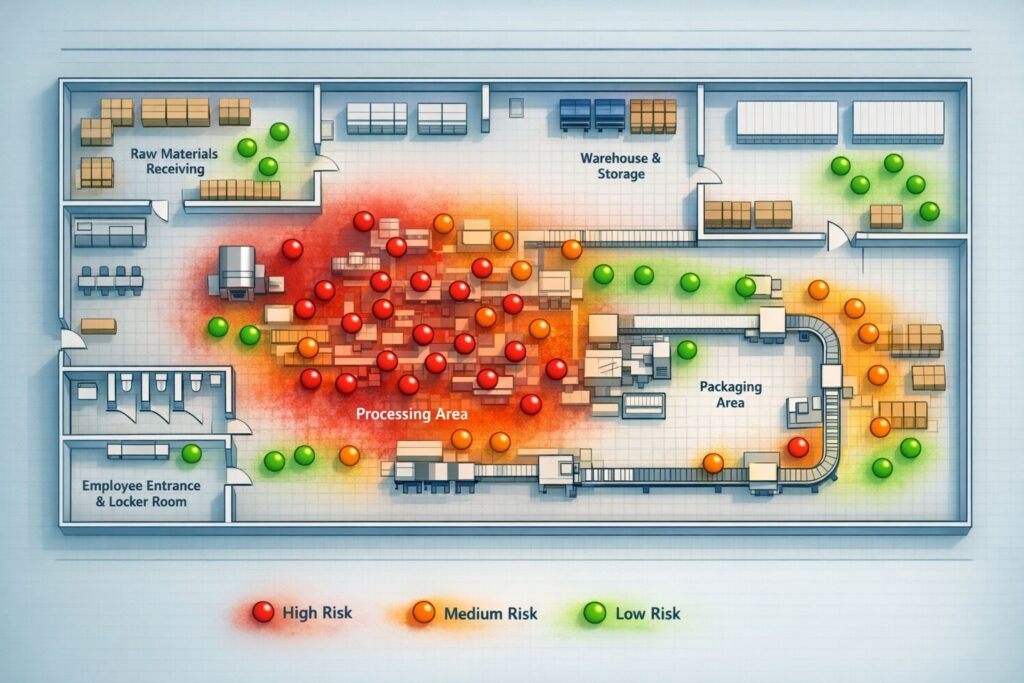

Sample Visual

Integrating EMP with Sanitation and IPM

FSMS software enables correlation between EMP results, sanitation performance, and pest activity, supporting faster root cause analysis and preventive actions.

Best Practices for Risk-Based EMP

• Regular review of sampling plans

• Trend-based analysis

• Integration with sanitation and IPM data

• Direct linkage to corrective actions

Better Data, Better Decisions

Risk-based EMP strengthens food safety by enabling early detection, smarter resource use, and audit confidence.

Next Steps

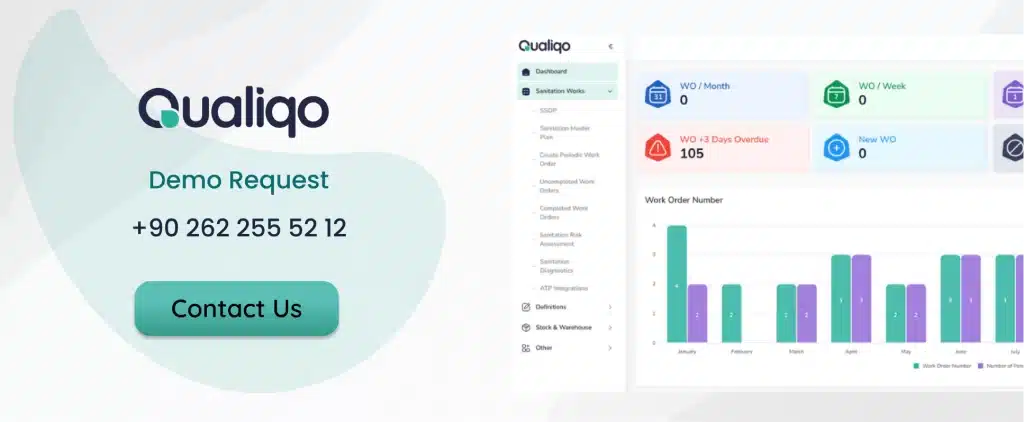

For food companies seeking efficiency, Qualiqo offers a reliable, all-in-one sanitation management solution. Qualiqo is designed to streamline food safety and sanitation processes for better operational control. It helps businesses track cleaning schedules, verify tasks, and meet food safety standards. Features include audit management, real-time alerts, and complete traceability across operations. With Qualiqo, food businesses embrace digital transformation and reinforce their food safety commitment.

Did you get enough information about “Risk-Based Environmental Monitoring Programs (EMP)“

Qualiqo is here to help you. It answers your questions about sanitation and hygiene, Lab. & EMP, IPM and Pest Control. We also provide information about the main features and benefits of the software.

We help you access the Qualiqo demo and even get a free trial.