Ensuring Effective Cleaning Control within FSMS

Sanitation practices are a fundamental component of food safety in production facilities. However, in many organizations, cleaning effectiveness is assessed primarily through visual inspections or periodic test results.

While these methods indicate whether cleaning activities were performed, they do not always demonstrate whether they were performed correctly and effectively. This confusion often becomes apparent during audits, where sanitation verification and validation are frequently misunderstood or used interchangeably.

Modern FSMS frameworks require sanitation to be managed as a measurable, verifiable, and scientifically supported process. Clearly defined verification and validation steps provide objective evidence of sanitation effectiveness.

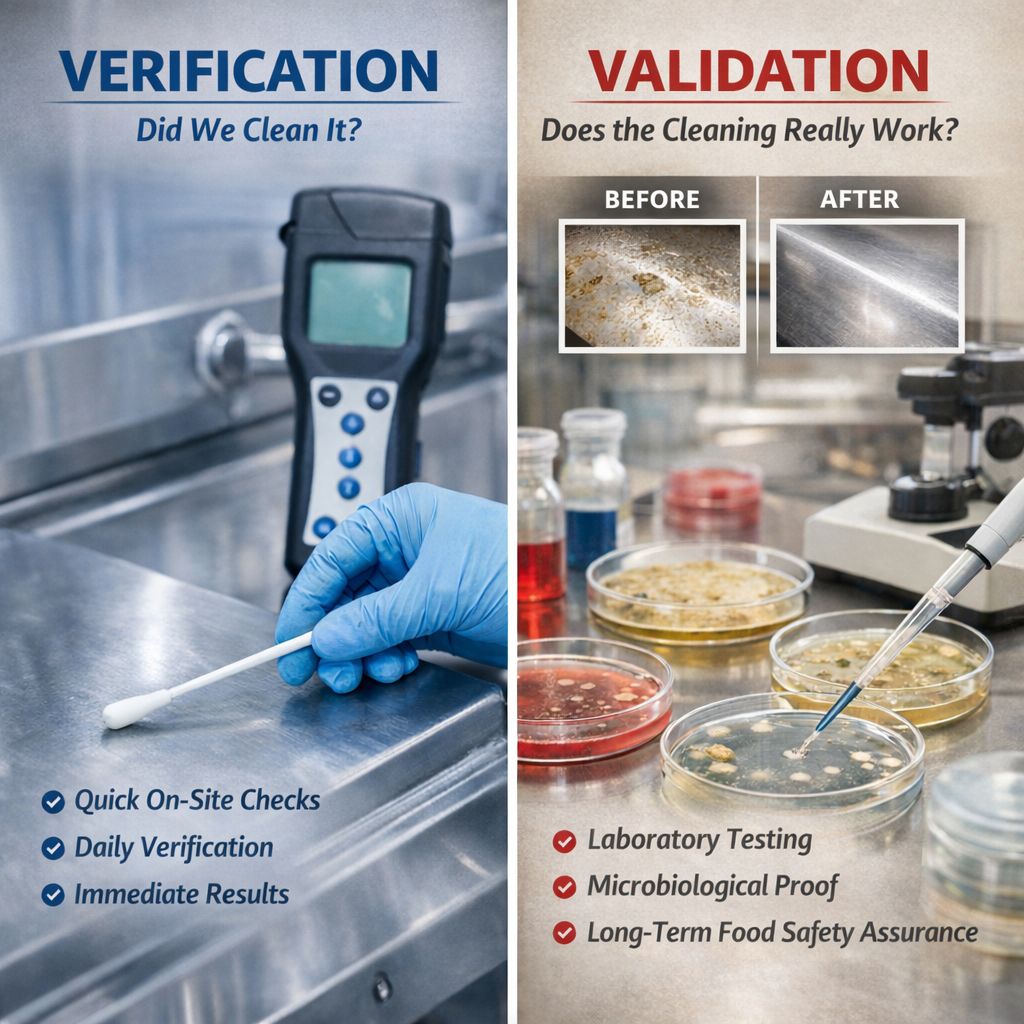

What Are Sanitation Verification and Validation?

• Validation demonstrates that the sanitation method and procedure are capable of achieving the intended food safety outcome

• Verification confirms that the validated sanitation process is implemented correctly and consistently

These two concepts are complementary but not interchangeable.

When and How Is Sanitation Validation Performed?

Validation is typically conducted

• during process or product changes

• when introducing new chemicals or equipment

• when updating sanitation procedures

It relies on scientific data to confirm effectiveness.

How Does Sanitation Verification Work?

Verification includes routine and periodic checks such as

• visual inspections

• ATP testing

• microbiological surface testing

• trend analysis

Key Differences Between Verification and Validation

| Criteria | Verification | Validation |

|---|---|---|

| Purpose | Confirm execution | Confirm suitability |

| Timing | Ongoing | Change-driven |

| Data Type | Operational | Scientific |

| Audit Role | Evidence | Justification |

Sample Visual

Managing Sanitation with FSMS Software

FSMS software enables centralized sanitation data collection, automated trend analysis, CAPA triggering, and audit-ready documentation.

Common Mistakes

• Treating verification results as validation

• Using insufficient data for validation

• Ignoring trend analysis

• Managing records solely for audits

Building a Robust Sanitation Control System

Clear distinction between sanitation verification and validation strengthens food safety control and audit confidence. FSMS ensures sanitation processes are measurable, traceable, and sustainable.

Next Steps

For food companies seeking efficiency, Qualiqo offers a reliable, all-in-one sanitation management solution. Qualiqo is designed to streamline food safety and sanitation processes for better operational control. It helps businesses track cleaning schedules, verify tasks, and meet food safety standards. Features include audit management, real-time alerts, and complete traceability across operations. With Qualiqo, food businesses embrace digital transformation and reinforce their food safety commitment.

Did you get enough information about “Sanitation Verification vs Validation“

Qualiqo is here to help you. It answers your questions about sanitation and hygiene, Lab. & EMP, IPM and Pest Control. We also provide information about the main features and benefits of the software.

We help you access the Qualiqo demo and even get a free trial.