Managing Hygiene and Manufacturing Standards Digitally

In food production, safety impacts not only product quality but also consumer health and brand reputation. Even a small oversight can lead to serious consequences. This is why standards such as GHP (Good Hygiene Practices) and GMP (Good Manufacturing Practices) are critical in the food industry.

However, traditional paper- and Excel-based processes are often insufficient to ensure compliance with these standards. Human error, lost records, and incomplete audits are common challenges. This is where digital solutions come in, making GHP and GMP compliance easier and safer for businesses.

What Are GHP and GMP?

GHP (Good Hygiene Practices) form the foundation of food safety. They cover employee hygiene, handwashing practices, protective clothing, cleaning, and preventing cross-contamination.

On the other hand, GMP (Good Manufacturing Practices) represent a broader framework that governs the entire production process. GMP includes facility and equipment hygiene, product quality standards, process validation, and measures to prevent cross-contamination.

In short, GHP focuses on daily hygiene and cleaning, while GMP provides a more systematic approach to ensuring the overall safety and consistency of production. Both are essential to minimizing health risks and ensuring legal compliance.

Key Elements of GHP and GMP

1. Employee Hygiene and Training

Food safety starts with employee hygiene. Regular training programs ensure workers understand and apply hygiene standards. Proper handwashing, use of protective clothing, and awareness of hygiene protocols are some of the most effective ways to prevent contamination.

2. Equipment and Facility Cleaning

The cleanliness of facilities and equipment is vital. Routine cleaning and sanitation programs minimize the risk of microbial growth and cross-contamination. Proper maintenance of equipment also ensures smooth and safe production processes.

3. Production Process Controls (GMP)

GMP ensures that the entire production process, from start to finish, complies with safety and quality standards. Quality control checkpoints, validated processes, and strict production protocols help prevent contamination and faulty products. GMP also emphasizes recordkeeping and traceability throughout production.

4. Auditing and Traceability

Audits and recordkeeping are essential for both GHP and GMP. Accurate records ensure transparency during internal and external audits. Corrective actions and automated alerts further strengthen these processes, making it easier to identify risks early and continuously improve operations.

The Role of Digitalization: Managing GHP and GMP with Qualiqo

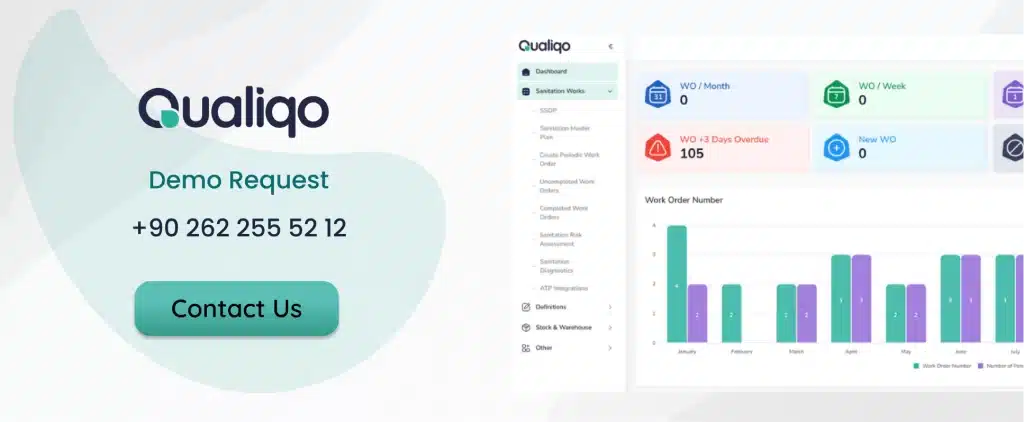

Paper and Excel-based systems are error-prone and inefficient. A digital solution like Qualiqo transforms GHP and GMP compliance into a streamlined, proactive, and reliable process.

- Real-time monitoring: Track hygiene and production processes directly from field teams.

- Automated alerts and reminders: Never miss hygiene checks, equipment maintenance, or quality control steps.

- Audit readiness: Generate reports instantly for inspections with no missing or inaccurate data.

- Data-driven decision making: Detect anomalies early and take corrective action quickly.

- Paperless and sustainable workflows: More efficient operations that are also environmentally friendly.

With digitalization, businesses save time and labor while significantly reducing food safety risks.

The Benefits of GHP and GMP Compliance

- Health and Safety: A safer environment for both employees and consumers.

- Regulatory Compliance: Easier alignment with HACCP, BRC, and ISO standards.

- Operational Efficiency: Fewer errors and disruptions, ensuring production continuity.

- Consumer Trust: Safe and high-quality products strengthen brand reputation.

- Cost Savings: Reduced waste, fewer product recalls, and less time spent preparing for audits.

GHP and GMP standards are the foundation of food safety and regulatory compliance in production. But managing these processes manually is often time-consuming and error-prone. Digital solutions simplify compliance, make processes more transparent, and ensure greater safety.

With Qualiqo, food businesses can optimize hygiene and manufacturing processes, minimize risks, and boost efficiency. The result is not only lower costs but also stronger consumer trust and a safer, more reliable food supply chain.

Next Steps

For food companies seeking efficiency, Qualiqo offers a reliable, all-in-one sanitation management solution. Qualiqo is designed to streamline food safety and sanitation processes for better operational control. It helps businesses track cleaning schedules, verify tasks, and meet food safety standards. Features include audit management, real-time alerts, and complete traceability across operations. With Qualiqo, food businesses embrace digital transformation and reinforce their food safety commitment.

Did you get enough information about “GHP and GMP in Food Safety“

Qualiqo is here to help you. It answers your questions about sanitation and hygiene, Lab. & EMP, IPM and Pest Control. We also provide information about the main features and benefits of the software.

We help you access the Qualiqo demo and even get a free trial.