Data-Driven Pest Management Integrated with EMP

For many years, pest management in food production facilities has been treated primarily as a control activity. Actions were taken only after pest activity was observed, records were reviewed mainly during audits, and problems were often addressed after they had already occurred.

However, increasing audit expectations, multi-site operations, and the growing emphasis on preventive food safety management have made this approach insufficient. Today, Integrated Pest Management must go beyond control and focus on early risk detection and proactive prevention.

This is where digital pest monitoring becomes a transformative element of modern IPM strategies. By digitally tracking pest activity and analyzing it alongside EMP and sanitation data, food manufacturers gain a data-driven and preventive approach to pest-related risks.

Why Pest Control Must Become Digital

Traditional pest control relies on reactive actions and delayed reporting. In modern food safety systems, this approach is no longer sufficient.

- Digital pest monitoring shifts IPM from

- incident-driven to risk-driven management.

What Is Digital Pest Monitoring?

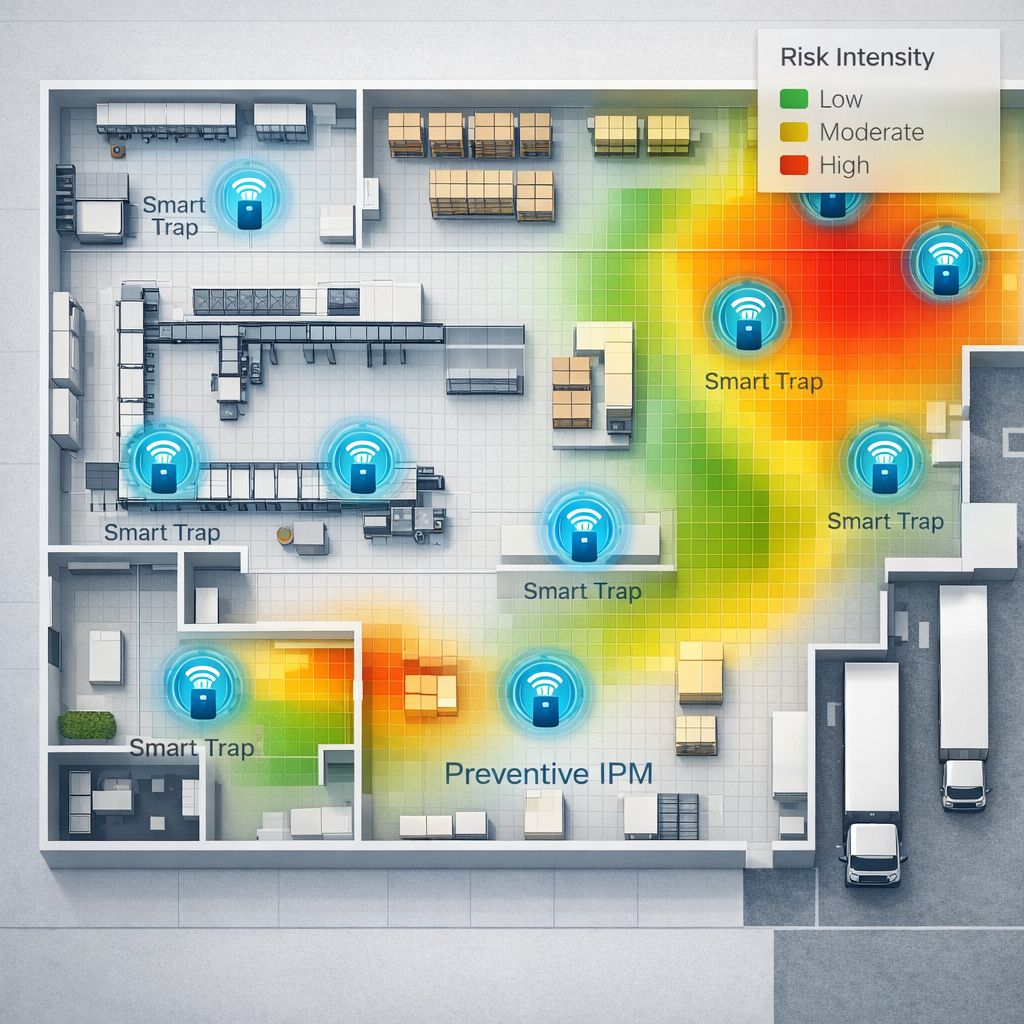

Digital pest monitoring is the continuous tracking of pest activity using digital records, location-based data, and trend analysis.

It provides clear answers to

• Where activity increases

• Which areas pose recurring risks

• How pest data relates to sanitation and EMP results

Traditional IPM vs Digital Pest Monitoring

| Traditional IPM | Digital Monitoring |

|---|---|

| Manual logs | Digital trap records |

| Periodic reports | Real-time visibility |

| Reactive actions | Preventive decisions |

| Limited insight | Data-driven analysis |

| Audit-focused | Risk-focused |

Sample Image

The Critical Link Between Pest Monitoring and EMP

Pest activity often indicates underlying hygiene or environmental weaknesses.

FSMS software enables

• Correlation between pest data and EMP results

• Faster root cause analysis

• More accurate preventive actions

This integration is essential for high-risk food operations.

Key Metrics in Digital Pest Monitoring

Table: Digital IPM Performance Metrics

| Metric | Description | Food Safety Impact |

|---|---|---|

| Activity Density | Pest activity by zone | Risk level |

| Repeated Hotspots | Recurring pest locations | Structural weakness |

| Response Time | Time to corrective action | Risk containment |

| EMP Correlation | Pest–EMP relationship | Hygiene validation |

| Audit Findings | IPM-related issues | Compliance |

Best Practices for Digital IPM Management

Leading facilities

• Analyze pest trends regularly

• Link pest activity with sanitation data

• Use EMP as a verification layer

• Manage IPM as an internal, data-driven process

Digital pest monitoring elevates IPM from control to prevention.

From Pest Control to Pest Monitoring

Digital pest monitoring is no longer optional.

It is a core component of modern FSMS architectures.

With FSMS software, IPM becomes

• Preventive

• Measurable

• Audit-ready

Next Steps

For food companies seeking efficiency, Qualiqo offers a reliable, all-in-one sanitation management solution. Qualiqo is designed to streamline food safety and sanitation processes for better operational control. It helps businesses track cleaning schedules, verify tasks, and meet food safety standards. Features include audit management, real-time alerts, and complete traceability across operations. With Qualiqo, food businesses embrace digital transformation and reinforce their food safety commitment.

Did you get enough information about “Digital Pest Monitoring for Preventive IPM in Food Safety“

Qualiqo is here to help you. It answers your questions about sanitation and hygiene, Lab. & EMP, IPM and Pest Control.Digital Pest Monitoring for Preventive IPM in Food Safety We also provide information about the main features and benefits of the software.

We help you access the Qualiqo demo and even get a free trial.