A Missing Link in Food Safety Management

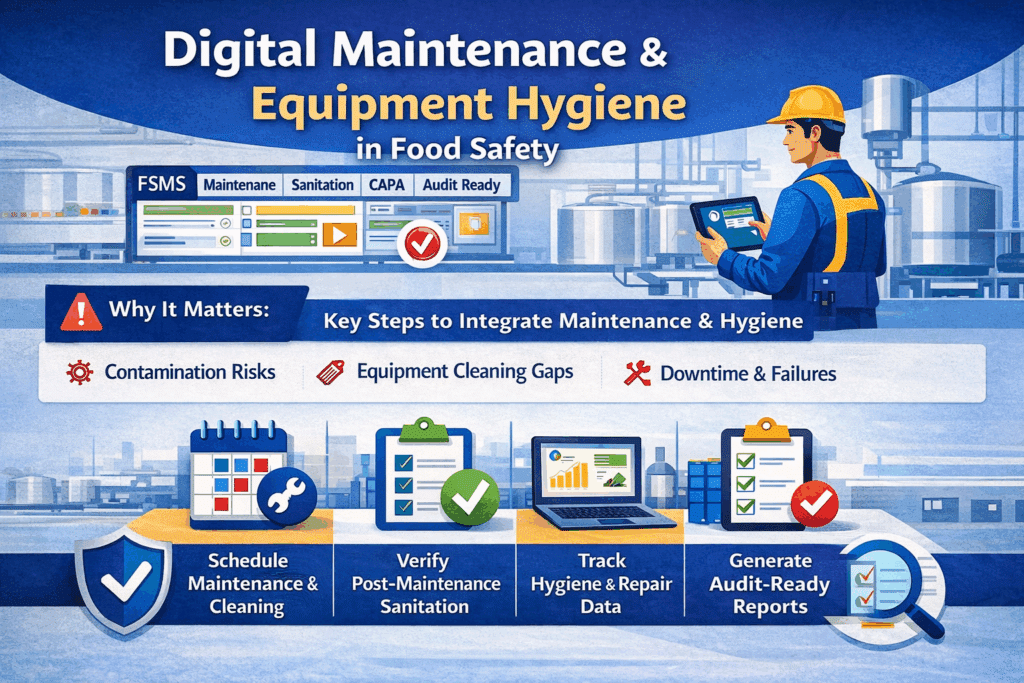

In food manufacturing, maintenance activities are often viewed through an operational lens—focused on uptime, efficiency, and cost control. However, from a food safety perspective, maintenance is far more than a technical necessity. Poorly managed maintenance processes can introduce significant contamination risks, compromise sanitation programs, and result in audit non-conformities.

Modern Food Safety Management Systems (FSMS) must therefore treat maintenance and equipment hygiene as integral components of risk-based food safety. Digital systems now make it possible to connect maintenance, sanitation, CAPA, and audit readiness within a single, traceable framework.

Why Maintenance Is a Critical Food Safety Risk Area

Maintenance tasks frequently involve:

- quipment disassembly

- Exposure of food contact surfaces

- Use of tools, lubricants, and spare parts

- Human intervention in high-risk production zones

Without structured control, these activities can lead to:

- Microbiological contamination

- Foreign body risks

- Inadequate post-maintenance cleaning

- Gaps in documentation during audits

Auditors increasingly expect food manufacturers to demonstrate how maintenance-related risks are identified, controlled, verified, and documented—not just whether maintenance was performed.

Equipment Hygiene After Maintenance: An Often Overlooked Step

One of the most common audit findings is the lack of post-maintenance sanitation verification. Completing a maintenance task does not automatically mean equipment is safe for production.

A robust FSMS should ensure that:

- Maintenance activities trigger sanitation requirements

- Cleaning and disinfection are verified before equipment release

- Hygiene status is visible and traceable

- Responsibilities are clearly defined across teams

Digital workflows eliminate assumptions and ensure that no equipment returns to production without proper hygiene approval.

Integrating Maintenance and Sanitation Digitally

When maintenance and sanitation are managed in isolated systems—or on paper—critical data remains fragmented. Digital FSMS platforms like Qualiqo enable organizations to:

- Link maintenance tasks directly to sanitation workflows

- Assign mandatory hygiene checks after maintenance completion

- Track verification and validation activities in real time

- Generate audit-ready records automatically

This integration strengthens operational control while significantly reducing manual follow-up and compliance risk.

Maintenance Data as a Preventive Food Safety Tool

Beyond documentation, maintenance data plays a key role in preventive risk management. Repeated failures, frequent interventions, or recurring sanitation issues often indicate deeper hygiene or design problems.

By analyzing maintenance and sanitation data together, food safety teams can:

- Identify high-risk equipment

- Prioritize preventive maintenance activities

- Trigger CAPA before issues escalate

- Support continuous improvement initiatives

This data-driven approach transforms maintenance from a reactive function into a preventive food safety control.

Meeting Audit Expectations with Digital Traceability

Auditors no longer focus solely on individual records. They assess system maturity, traceability, and effectiveness.

Digital maintenance and hygiene management helps demonstrate:

- Clear linkage between maintenance, sanitation, and CAPA

- Timely closure of corrective actions

- Consistent application of hygiene rules

- Evidence-based decision-making

With centralized dashboards and automated reports, audit preparation becomes an ongoing process—not a last-minute effort.

Maintenance Belongs at the Core of FSMS

In modern food safety systems, maintenance is not just an operational necessity—it is a food safety control point. Integrating maintenance, equipment hygiene, and sanitation within a digital FSMS strengthens compliance, reduces contamination risk, and supports sustainable audit readiness.

By closing the gap between maintenance and food safety, organizations move one step closer to a truly preventive, risk-based FSMS.

Next Steps

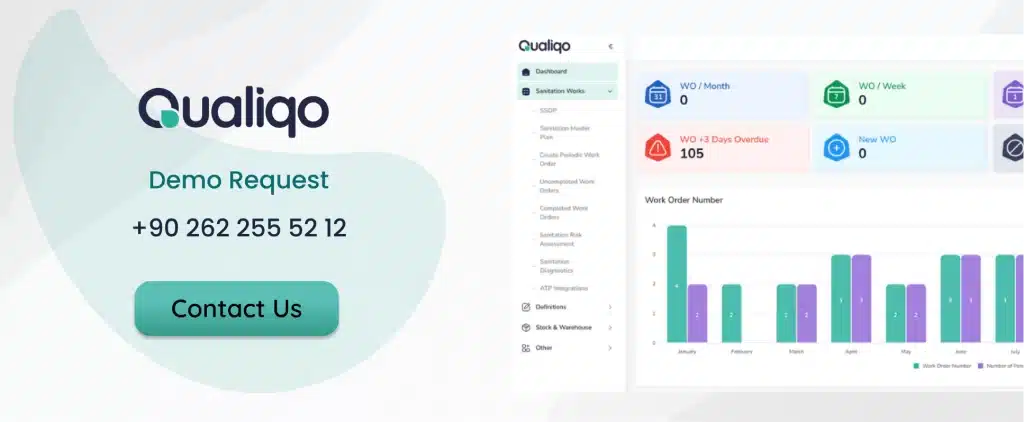

For food companies seeking efficiency, Qualiqo offers a reliable, all-in-one sanitation management solution. Qualiqo is designed to streamline food safety and sanitation processes for better operational control. It helps businesses track cleaning schedules, verify tasks, and meet food safety standards. Features include audit management, real-time alerts, and complete traceability across operations. With Qualiqo, food businesses embrace digital transformation and reinforce their food safety commitment.

Did you get enough information about “Digital Maintenance and Equipment Hygiene“

Qualiqo is here to help you. It answers your questions about sanitation and hygiene, Lab. & EMP, IPM and Pest Control. We also provide information about the main features and benefits of the software.

We help you access the Qualiqo demo and even get a free trial.