Key Innovations in Rapid Food Safety Testing

Food safety is a top priority for every company in the food industry. In today’s fast-moving global supply chains, the challenge is clear: how can we detect potential hazards before they reach consumers? Traditional microbiological testing methods often take several days to deliver results, leaving a dangerous window where contamination can spread.

This is why rapid testing innovations in food safety are reshaping how producers, processors, and regulators manage risks. By combining advanced laboratory methods with digitalization and automation, rapid testing is enabling real-time insights, proactive decision-making, and stronger consumer protection.

Why Rapid Testing Matters

Foodborne pathogens such as E. coli, Salmonella, and Listeria monocytogenes remain among the leading causes of recalls worldwide. A single outbreak can cost millions in lost product, legal fines, and brand reputation damage.

Rapid testing technologies reduce the time between sampling and results from several days to just a few hours—or even minutes. For food producers, this speed translates into:

- Faster release of safe products

- Reduced risk of contaminated batches entering the market

- Better compliance with regulations such as FSMA, HACCP, and ISO 22000

- Stronger Environmental Monitoring Programs (EMP)

- Improved traceability during recall investigations

In short, rapid testing empowers companies to shift from reactive problem-solving to preventive risk management.

Key Innovations in Rapid Food Safety Testing

1. Polymerase Chain Reaction (PCR) Testing

PCR is one of the most widely adopted rapid testing methods. It works by amplifying genetic material from pathogens, enabling quick detection of organisms like Salmonella, Listeria, and E. coli.

- Advantages: Results in hours instead of days; highly sensitive and specific.

- Use cases: Screening raw ingredients before production; verifying sanitation effectiveness on equipment surfaces.

For sanitation management teams, PCR allows for immediate corrective action if contamination is detected.

2. Whole Genome Sequencing (WGS)

WGS has transformed outbreak investigation. Unlike traditional testing, WGS provides a complete genetic fingerprint of pathogens. This enables regulators and companies to track contamination sources with unmatched precision.

- Advantages: Extremely accurate; enables traceability across the entire food supply chain.

- Use cases: Linking outbreaks across multiple regions; proving or disproving contamination links between suppliers and finished products.

By adopting WGS, companies gain deeper insights not only into “what” contamination occurred but also “where” and “how” it originated.

3. Biosensors and Lab-on-a-Chip Devices

Emerging biosensors allow real-time, on-site detection without needing a fully equipped laboratory. These handheld or automated devices use nanotechnology, optical signals, or electrochemical reactions to identify contaminants.

- Advantages: Portable, cost-effective, and extremely fast.

- Use cases: Monitoring water quality, testing surfaces in high-risk zones, and screening raw produce.

These innovations support Environmental Monitoring Programs (EMP) by providing instant feedback, allowing teams to respond before risks escalate.

4. Next-Generation Sequencing (NGS)

NGS is pushing the boundaries of microbiology. Unlike WGS, which focuses on single organisms, NGS can analyze entire microbial communities in a sample.

- Advantages: Detects both harmful pathogens and background flora that may influence contamination risks.

- Use cases: Supporting contamination control in complex environments, monitoring microbial shifts in ready-to-eat facilities, and strengthening Integrated Pest Management (IPM) programs.

NGS helps food companies move toward predictive microbiology, anticipating problems before they occur.

5. Digital Integration with Food Safety Software

The real power of rapid testing comes when it is integrated into digital food safety management systems.

Imagine this scenario:

- A PCR test flags Listeria on a production line.

- The result is automatically uploaded into a sanitation management platform.

- The system generates a corrective action workflow, assigns responsibilities, and documents the outcome for audits.

This level of automation and traceability saves time, reduces human error, and ensures compliance with internal and external standards.

Case Example: Rapid Testing in Action

Consider a frozen vegetable manufacturer. Previously, routine testing required holding products for three days before release. By adopting PCR and biosensors, results now arrive in less than 24 hours. This has enabled:

- Faster product release and reduced storage costs

- Early detection of Listeria monocytogenes in the facility’s environment

- Real-time corrective actions, such as targeted sanitation and retesting

The result: improved operational efficiency and greater confidence in food safety.

Benefits for Food Producers and Consumers

For producers:

- Faster decision-making and reduced downtime

- Cost savings by minimizing recalls and waste

- Stronger compliance with global regulations

- Seamless audit readiness with digital records

For consumers:

- Safer products on the shelves

- Greater transparency and trust in brands

- Confidence in allergen management and contamination prevention

Next Steps

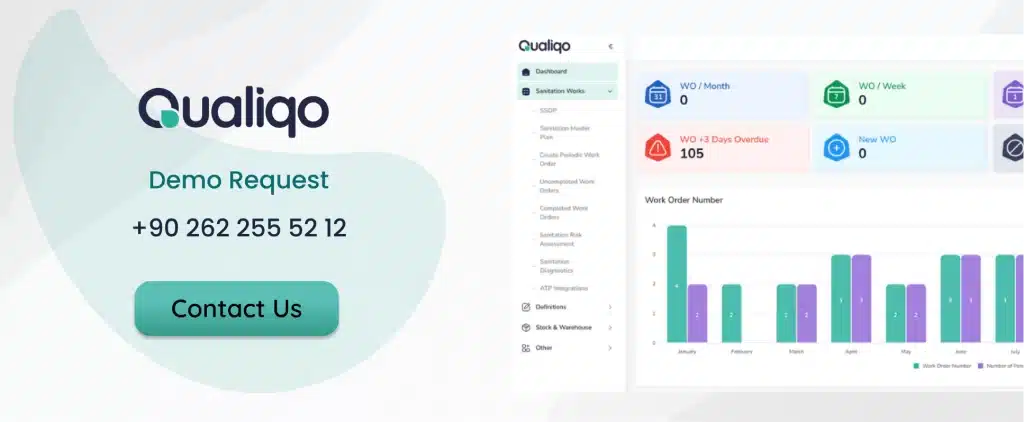

For food companies seeking efficiency, Qualiqo offers a reliable, all-in-one sanitation management solution. Qualiqo is designed to streamline food safety and sanitation processes for better operational control. It helps businesses track cleaning schedules, verify tasks, and meet food safety standards. Features include audit management, real-time alerts, and complete traceability across operations. With Qualiqo, food businesses embrace digital transformation and reinforce their food safety commitment.

Did you get enough information about “Rapid Food Safety Testing“

Qualiqo is here to help you. It answers your questions about sanitation and hygiene, Lab. & EMP, IPM and Pest Control. We also provide information about the main features and benefits of the software.

We help you access the Qualiqo demo and even get a free trial.

Frequently Asked Questions (FAQ)

Rapid testing refers to advanced methods that detect foodborne pathogens, allergens, or contaminants in a much shorter time compared to traditional microbiological testing. Techniques like PCR, WGS, biosensors, and NGS allow results within hours or even minutes.

It helps food companies release products faster, reduce storage costs, prevent costly recalls, and ensure compliance with global food safety standards. Rapid testing also supports proactive risk management by identifying hazards before products reach consumers.

The most popular methods include:

PCR (Polymerase Chain Reaction) – fast and precise detection of pathogens

Whole Genome Sequencing (WGS) – detailed genetic fingerprinting for outbreak investigation

Biosensors and Lab-on-a-Chip devices – portable, real-time monitoring

Next-Generation Sequencing (NGS) – analyzing entire microbial communities